medically compressed air system testing|compressed air testing guidelines : retailer A good-size hospital with 200 beds and ten operating rooms can have a medical air system, a laboratory air system, and pneumatic air systems. The medical air systems must all follow the NFPA 99 guidelines. Resultado da 11 de out. de 2023 · masteruwuoficial. Soy un creador de contenido al quien le gusta el H y las monas shinas, e creado este grupo con el fin de .

{plog:ftitle_list}

Resultado da Está a procura de acompanhantes mulheres na cidade Paranatinga? No Fatal Model você encontra! Veja acompanhantes verificadas próximas .

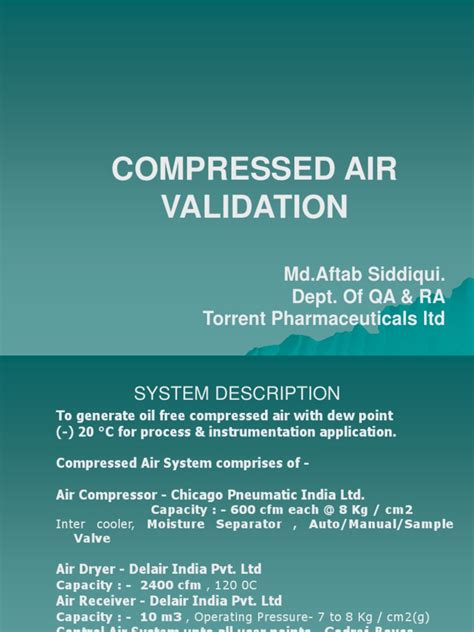

compressed air validation

A good-size hospital with 200 beds and ten operating rooms can have a medical air system, a laboratory air system, and pneumatic air systems. The medical air systems must all follow the NFPA 99 guidelines.

Testing your compressed air is simple with Trace Analytics. We’ll set you up with easy to follow instructions, comprehensive videos to guide you, a third-party distributer if you choose, and a .A medical device compressed air system should include a properly maintained compressor, adequate piping and distribution, and effective filters. It’s .Pharmaceutical Process Air & Gas Testing. Compressed air is a critical utility used widely throughout pharmaceutical manufacturing processes and it is used both directly and indirectly with pharmaceutical products. Pharmaceutical .

DIN Abrasion Tester trading

compressed air testing procedure

7356-002E Compressed Medical Gases. FIELD REPORTING REQUIREMENTS. Establishment Inspection Reports (EIRs) are to be created and filed electronically employing a medical gas .

Learn about the importance of validating Compressed Air Systems in the pharmaceutical industry, following ISPE, USP, and other regulatory guidelines. We monitor and detect target gases commonly found in compressed air systems of hospitals and medical facilities. In these systems, a medical air compressor produces air at 100 psig and feeds it at this same .ISO Standard 8573-1 is one of the most used standards that classifies compressed air into varying levels of quality (i.e., purity and cleanliness), and most medical equipment will require a quality falling into one of the classes the .Recent NFPA99 editions require those who are maintaining medical air and medical vacuum systems, to be properly qualified and credentialled. These qualifications include an ASSE 6040 certification from an accredited source.

%PDF-1.6 %âãÏÓ 17454 0 obj >stream hÞì›[¯$DZ ÿÊ~´ ¤‰[Þ€ :òƒ Ë„(? ‚0–F Š$x Ì ïìÚ½¾&gÆÃáåXÆQ¾ÄÄTDfu¯ŠªZ±;V-{²§Zþä6ö .

Medical air applications: • Mechanical ventilation and anesthesia. • Drug delivery via a nebulizer. • Testing and drying of medical devices. Surgical air applications: • Pneumatic surgical tools (drilling, reaming, sawing, dissecting, tapping and screwing). • Pneumatic ceiling pendant operation. • Testing of medical devices.The Dräger compressed air systems use 3 separate compressors, each with 2 redundant pressure tanks, filter systems, compressed air conditioners and pressure reducer stations. This makes maintenance and repairs possible without interruption of the air supply, offering additional operational security.In addition to knowledge of product maintenance, a Medical Gas Maintenance worker is required to have a general knowledge of the applicable laws, codes, rules, listing agencies, and regulations from the federal, state, and local levels pertaining to medical gas and vacuum systems as well as knowledge of product performance, system and system .

Compressed air systems consume a significant portion of the electricity used by manufacturing plants. A compressed air audit can identify inefficient compressed air systems that need to be addressed in order to achieve reliable product quality, reduce energy consumption and improve productivity. Compressed air quality is an important part of an audit. Poor air quality.Compressed Gas/Air System Testing. Compressed gas/air systems are critical process systems which require routine maintenance and testing for confirmation of control to established cleanliness parameters. From the biopharma, medical device and healthcare industries to food and beverage production, TSS provides complete compressed gas testing and . In most cases, end users select compressed air system components by comparing technical data from various air treatment manufactures. In 1991, the International Standards Organization (ISO) established the 8573 compressed air quality standard to facilitate compressed air system component selection, design and measurement.

Reciprocating Friction Tester trading

Since compressed air is a critical factor in the manufacturing of medical devices, this applies to compressed air systems as well. Contaminated compressed air can compromise the integrity of the medical device products and put consumers at risk. Compressed air must meet medical device quality standards and manufacturers have to provide .

Compressed Air Testing for Breathing Air and Manufacturing with the experts at Trace Analytics. . K6042 Breathing Air Gas Contaminant Testing Kit; K6099 Medical Gas Testing Kit; Manufacturing / ISO 8573 Air . and regular testing can prevent serious contamination and promote the overall health of the system. Test your compressed air to ISO .

Background. In Part 1, I made the case that full system commissioning is needed whenever a compressed air system is significantly modified.And I suggested the following definition of commissioning: “Compressed air system commissioning is the process for measuring, testing, adjusting, and documenting that the performance of an entire .

In the 2010 edition of ISO 8573-1, the particle size and maximum number of particles were harmonized with current filter manufacturer’s capabilities. This harmonization created an effective method to communicate requirements for a compressed air system between the end user, filter and compressor manufacturer, and testing laboratory. Compressed air is a critical utility that is widely used throughout the food industry. Many of the GFSI schemes like Safe Quality Food (SQF), British Retail Consortium (), primusGFS, and Food Safety System Certification 22000, require compressed air quality monitoring.FDA’s Food Safety Modernization Act requires covered manufacturing facilities to .Solutions for medical gas testing standards including NFPA 99. Fire Service. . Dive. Compressed air testing for SCUBA CGA Grade E, PADI, IANTD, ANDI Dive Air, oxygen compatible and more. US Military. We continue to sponsor the U.S. Navy as well as other branches of the United States Millitary. Latest Blogs. K6042 Breathing Air Gas Contaminant Testing Kit; K6099 Medical Gas Testing Kit; Manufacturing / ISO 8573 Air. K810 P:W:O Testing Kit . should be equipped with the necessary preventative measures including, filters, dryers, traps, and sampling ports. Most compressed air systems are designed, controlled, and maintained in a dry state to prevent .

Medical gases are regulated as finished pharmaceuticals regardless of the stage of processing. Medical gases must be manufactured (e.g., processed, filled, transfilled, mixed, purified,The Dräger compressed air systems use 3 separate compressors, each with 2 redundant pressure tanks, filter systems, compressed air conditioners and pressure reducer stations. This makes maintenance and repairs possible without interruption of the air supply, offering additional operational security.

The EVair medical air compressor (EVair) is intended to be connected to a Datex-Ohmeda Inc. critical care ventilator [CARESCAPE R860] as a supply of compressed medical breathing air (compressed air).8-Maintenance of Compressed Air Systems for Peak Performance 53 9-Heat Recovery and Compressed Air Systems 59 10-Baselining Compressed Air Systems 61 11-Determining Your Compressed Air System Analysis Needs 65 12-Compressed Air System Economics and Selling Projects to Management 69 Section 3: Where To Find Help BestPractices 75 Medical gases, commonly known as 'med gas,' are pivotal in modern healthcare, providing vital support in various medical procedures and patient care. These specialized gases, including oxygen, nitrous oxide, medical air, carbon dioxide, helium and various mixtures are integral in multiple applications—from anesthesia and respiratory therapy to sterilization and .

sources of contamination, the individual contaminants found within a compressed air system and the problems that contaminants can cause: Sources of contamination in a compressed air system . PARTS 2 – 9 SPECIFY THE METHODS OF TESTING FOR A RANGE OF CONTAMINANTS. ISO 8573.1 : 2001 is the primary document used from the ISO 8573 series .You can use the kit to test your breathing air qua lity from your compressor or cascade system. AirCheck Kit Model K902 is Trace’s solution to affordable testing per NFPA 99 standards. This kit allows for sampling of Carbon Dioxide, Carbon Monoxide, Methane, Nitrogen, Oxygen, Moisture, Odor, Oil Mist and Particles, and Hydrocarbons.Amico Source Medical Air System Selection Table (Oil-Less Scroll Systems) 60-61 Amico Source Medical Air System Selection Table (Oil-Less Reciprocating Systems) 62-63 System Selection Tables Notes 64 5.2.7 Step 7: General Layout 64-66 5.2.8 Step 8: Specification & Schedule 66 Chapter 6 – Medical Vacuum (Suction) Systems 69-94 Medical Vacuum .Microbial Testing of Compressed Air Micro Testing of Compressed Air or Bioburden Testing per ISO 8573-7 is generally conducted by the pharmaceutical, medical device and food industries. Microbial contaminants found in the compressor or compressed air lines can be devastating to a final product in these industries. A regular Micro Testing program can provide .

TRI Air Testing is an ISO 17025:2017 Accredited Laboratory specializing in the analysis of compressed breathing air and pure gas quality testing for firefighters and SCBA Air. Compressed air plays a huge role in keeping firefighters safe in hazardous environments. TRI AirTesting compressed air and pure gas testing kits help fire departments to .Compressed Air Testing As a dedicated provider of compressed air testing solutions, our accredited laboratory specializes in analyzing compressed air and gas for a wide range of industries, including manufacturing and medical facilities. Contact us ISO 8573 The ISO 8573 Purity Class chosen for a manufacturing facility depends on its specific use of compressed air.

Enclosed Air Compressor Systems Let's Stay Connected Subscribe to our newsletter to receive exclusive insights on new product launches and industry trends, along with educational material, straight to your inbox.

Medical Scroll Air Compressor Systems: Pattons Medical scroll compressor systems are built for simplicity of maintenance, a small footprint, and quiet operation. Our oil-less scroll compressor configurations are the industry's smallest medical compressed air packages, complete with air compressor, desiccant dryer, filters, dewpoint monitors, and CO monitors.

compressed air testing pharmaceutical

webUm olhar cru e revelador da vida dos adolescentes em 2003.

medically compressed air system testing|compressed air testing guidelines